Today we’re taking a closer look at a company that ticks two of the hottest asset class boxes in alternatve investing – a real estate startup. Whether you like making money from property or cool new businesses, we’ve got you covered. Azure Printed Homes is a 3D printing company that can build an ADU for a fraction of the cost and time than traditional building methods. Plus, they’ve just opened for investment on Republic, with a very accessible minimal investment of $500.

Let’s check them out.

Table of Contents

3D printing has evolved

Many of you have probably heard about 3D printers, but you may not know just how far this technology has advanced over the past decade.

3D printers started out as kind of a novel concept in the 1980s to increase the efficiency of manufacturing. Fast-forward forty years, and its applications have blossomed.

The American military uses 3D printers to create parts for UAVs, and scientists are in the process of developing technology for printers to replicate human organs, and so on…

Azure Printed Homes uses them for a particularly interesting and innovative purpose – to build economically viable, sustainable and fast real estate.

The opportunity:

- Crowdfunding platform: Republic

- Raising: $1.07M

- Valuation: $24MM

- Minimum investment: $500

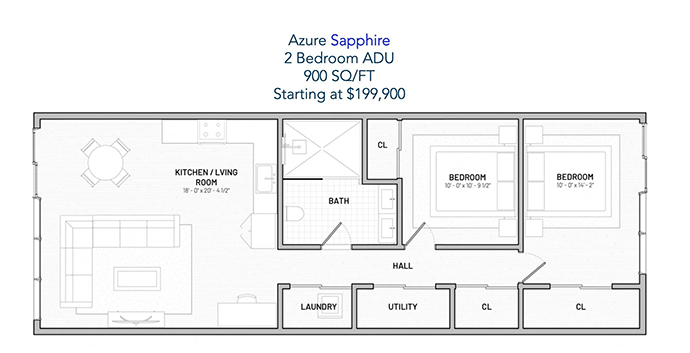

Azure Printed Homes leverage 3D printing technology to bring a whole new method to creating beautiful homes, studios and accessory dwelling units (ADUs). Best of all, it is a significant improvement on the environmental standards of modern-day construction.

How Azure Printed Homes began

Azure Printed Homes was founded just a few years back, in 2019, by Ross Maguire and Gene Eidelman. Between them, they boast over 50 years of construction experience developing houses across a number of continents. But in their time working in the industry, something was missing.

Maguire and Eidelman recognized that the world of construction was stalling. Developers continued to use the same outdated methods that had become popularized centuries ago. The result?

Properties are being built over budget, with continuous delays, and worst of all – with excessive waste. Not only was the stagnant industry cost-inefficient, but it was also harming the world we live in. The founders knew that there must be a better way to go about building homes, and they set out to work on an alternative.

Their business was created with three key construction philosophies in mind:

- More economically viable

- Deliver buildings on-time

- Improve environmental sustainability.

How Azure 3D printing works

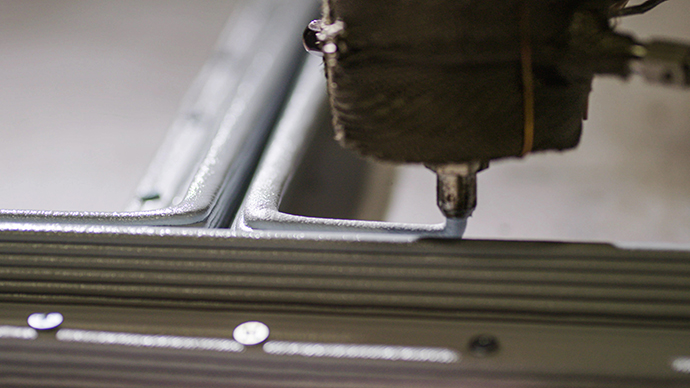

3D printing technology has made “revolutionary gains” over the past few years. It has all sorts of practical applications – and Maguire and Eidelman realized its potential. By utilizing recycled plastic polymers, Azure Printed Homes can create studios, offices, and properties that are extremely easy to set up on-site.

Combining 3D printers and recyclable plastic materials has a three-fold effect, smashing each goal the founders set for their business. Studios, ADUs, and offices can be prefabricated, meaning they are built about 70% faster than traditional construction methods. Given the use of reprocessed materials, costs are cut by about 30% too.

But the biggest gains are being made environmentally. According to a 2019 study by the United Nations, the construction industry accounts for a whopping 20% of global CO2 emissions. Construction is also by far the world’s largest consumer of raw materials, and less than 30% of recyclable materials ever end up being repurposed.

With net-zero a target for a number of nations by 2030, the construction industry has to have a revolution. Azure Printed Homes might just be at the forefront of it. Using 3D printers and recycled plastics to build dwellings significantly reduces waste and emissions. It’s a sustainable model and one that other construction businesses will have to consider if they are to minimize their impact on the environment.

What sets Azure Printed Homes apart?

This really is a first-of-its-kind company, unlike some others that have unique target audiences or niches that drive their businesses. They are currently the only construction company to recycle polymer plastics as a primary building material. No one else in the world 3D prints entire housing structures – that’s floor – to roof – to wall – to floor.

The industry has responded positively to Azure’s innovation. Since their website was launched in January this year, they’ve already received over $3.75 million for units, ADUs and offices.

Perhaps their biggest coup was their partnership with Oasis Development. Oasis has backed them to deliver fourteen 3D-printed homes. The turnaround time is expected to be impressive – Azure will start work in November 2022, and plan to deliver the finished product only a month later.

The 3D properties

When you hear that Azure Printed Homes are creating properties with 3D printers, you may feel skeptical about how good the products can actually be. A quick look at some of their images will quickly dispel this notion – they are honestly pretty breathtaking.

The clean lines, the efficiency in time, money, environmental impact… We’re fans.

Founder Ross Maguire sums up their product quite well:

“We have created production efficiencies, not only by capitalizing on the advances in 3D printing but by creating a design and process that is completed in only 12 hours…When compared with conventional construction, we produce the entire structural skeleton, the exterior sheathing, the water control barrier, the exterior finish, the passageways for utilities, and the grounding for interior finishes, in a fraction of the time and cost. By revolutionizing a new age of home building with our sustainable, automated, and exact production processes, we see a very, very exciting future ahead.”

Wrapping up

What Azure Printed Homes is doing is super exciting.

Their product isn’t just filling a gap in the market – it may very well be revolutionizing it. With governments and society beginning to clamp down on waste and finally focus on saving the environment, 3D printing might just be what the construction industry needs.

Just what the future holds for this company is anybody’s guess. But if their uptake in just a few months of operations is any indication, it is going to be a very bright one.

That’s it for today’s issue, we hope you enjoyed it.

Is there anything you’d like us to look at? Any topics you’d like us to go over, or a particular opportunity you want us to analyze? Just get in touch – we read every single email.

Cheers,

Stefan